NewRAD CNC with GCode Draw

NewRAD CNC with GCode Draw are two software programs in one integrated design. NewRAD CNC is a CNC controller that works with all GRBL-based CNC machines. GCode Draw is a 2D Draw Program with built-in 2 1/2D GCode generator. Having both programs integrated into one application greatly increases the ease of use, and speed of the entire CNC process, from design to end product. It's a great way to get things done quickly and easily. Seamlessly.

The two software packages together are designed to get a typical hobby CNC user up and running as quickly as possible, and to do so with the lowest possible learning curve, and greatest ease of use. Perfect for the creative CNC hobbyist, especially those just starting out.

The free version will let you setup and test your CNC machine, run the motors, and run all the included sample GCode files. It will also let you test out all the draw functions in GCode Draw.

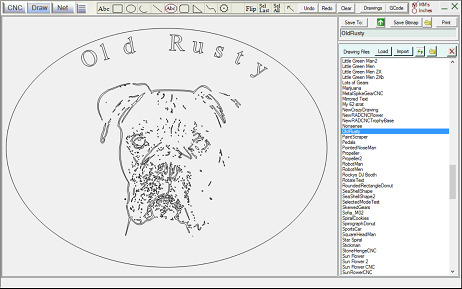

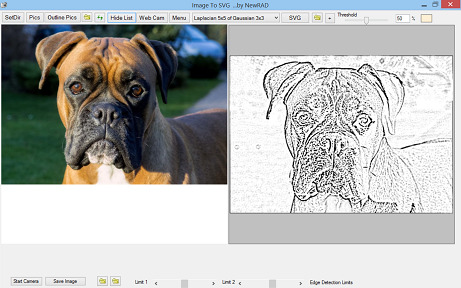

NewRAD CNC with GCode Draw are part of the NewRAD CNC Software Suite that currently contains the following 3 CNC softwares. The third software, Image To SVG let you convert images to SVG files. You can then import those SVG files into GCode Draw, where you can add graphics, then generate GCode, and then send that GCode to the NewRAD CNC Controller with one click. The 3 softwares work together seamlessly for maximum speed and ease of use.

Download it here: NewRADCNCSetup.exe (version 1.3, last revision 1/26/2024) When installing, Windows will give a security alert. Click on "More info", then "Run Anyway". Requires Full HD 1920x1080 screen resolution.

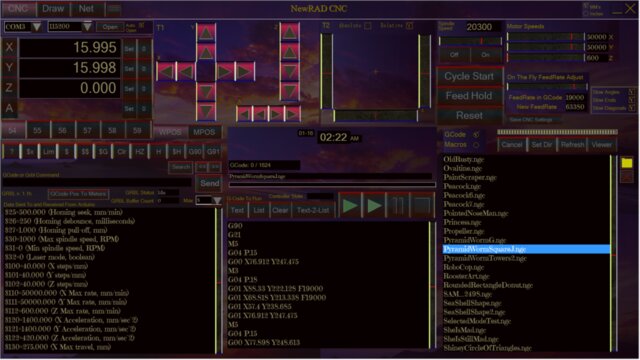

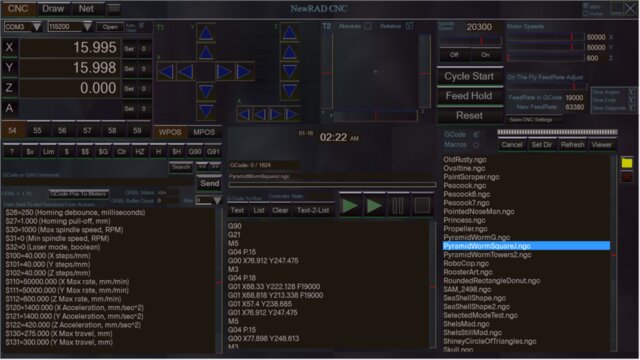

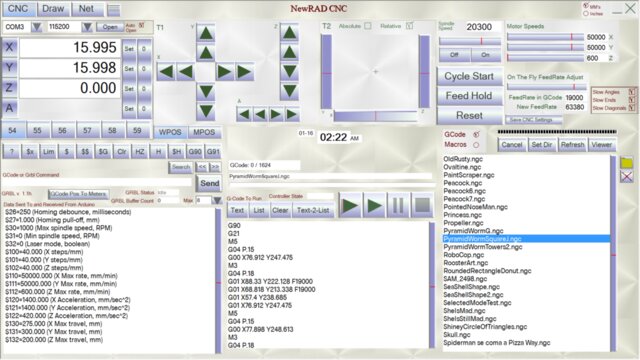

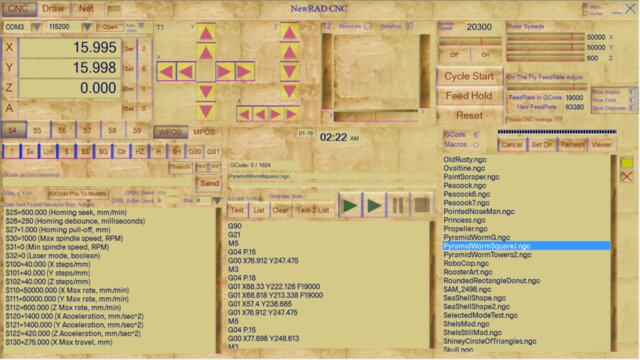

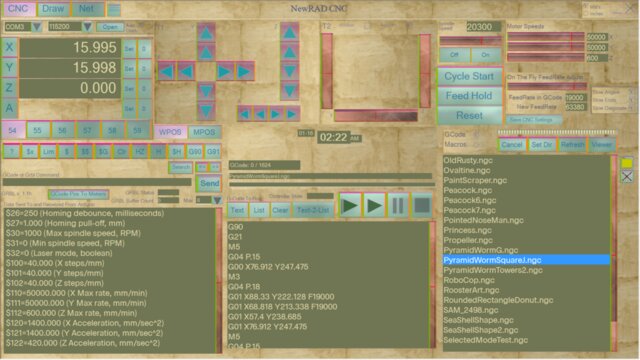

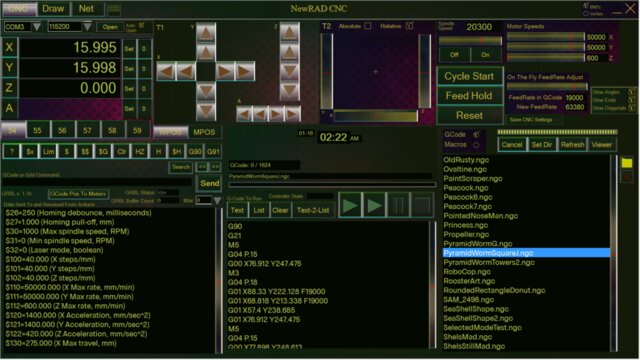

NewRAD CNC (GRBL Controller)

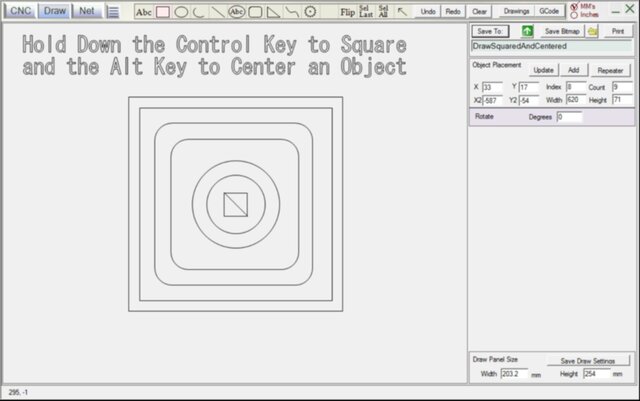

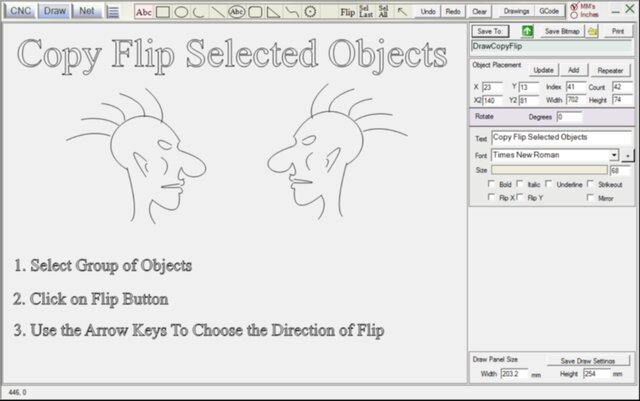

GCode Draw (2D Draw Program with GCode Generator)

Watch the video:

NewRAD CNC and GCode Draw can be purchased together or separately.

Features Free Version NewRAD CNC GCode Draw NewRAD CNC with GCode Draw Draw Stuff Yes Yes Yes Yes Save Drawings No Yes Yes Yes Control CNC Machine Yes Yes Yes Yes Run all the GCode files included with the software, and small amounts of your own GCode for testing. Yes Yes Yes Yes Run GCode No Yes No Yes Generate GCode from Drawings No No Yes Yes Change GUI Skins Yes Yes Yes Yes Price Free Download it here: NewRADCNCSetup.exe When installing, Windows will give a security alert. Click on "More info", then "Run Anyway". Requires Full HD 1920x1080 screen resolution.

NewRAD CNC Overview

NewRAD CNC is a high-quality, full-featured, 4-axis, Windows-based CNC controller software, with Auto Level, made specifically for GRBL-based CNC machines. It is very comfortable to use. Almost all operations are just a click away.

NewRAD CNC has the following features:

Rock-Solid Communication with the GRBL

Fast responsive position metering

Propietary Methods and Algorithms for communication with GRBL resulting in high operating performance, reliability and responsiveness.

Auto Level that is exactly proportional to the XY location of the tool head in relation to the Height Map for super precise auto leveling.

Probe Buttons for multi-axis XYZA probing, and single axis probing, and setting to zero.

Fine and Super Fine buttons added to Transport T1, for very small transport moves.

Macro Buttons for quick access to custom macros.

Quick Commands Toolbar for commonly used commands

2 Luxurious Transports for manual CNC motor control, yielding 3 different styles of motor control, augmented with Ctrl/Shift/Alt keys.

Fine and Super Fine Modes in T1 Transport for moving very small distances of .1mm or .01mm, or equivalent inches. Optional Automatic Connecting to Arduino when loading application

Built-in G54 through G59 programmable presets

Work-position and machine position metering views

4-axis Metering (X,Y,Z,A)

4-axis Set Position buttons

4-axis Set to Zero buttons

4-axis Transport controls

Keyboard control using Arrow keys, or F9-F12 keys for X and Y axis, and PageUp/PageDn keys for Z axis.

Ability to Extend T1 Transport Control Ranges, using the Control, Shift and Alt keys to change T1 Transport buttons from 1mm and 5mm to .1mm and 10mm, or .01mm and 15mm, or.001mm and 20mm, respectively, for finer or coarser jogging. New On-Screen Alerts for when Control, Alt, and Shift keys are pressed.

Spindle Motor Speed Adjustment slider control and on/off buttons

Stepper Motor Speed Adjustment slider controls for X, Y, Z, and All Motors at the same time with one click on the slider

FeedRate Adjustment up to 400% of FeedRate in GCode that is currently running, via slider control, or speed entered directly in text box

Ability to Save CNC Settings, recalled on next start up

GCode Files/Macro Files mode/view button

Separate List boxes for GCode and Macros, so both can be loaded at the same time with instant recall back and forth between GCode and Macro files

GCode and Macro Files are displayed on the main screen for instant access. No searching through directories to find your GCode and Macro files.

Buttons for 3 Types of Homing (Calibration) routines: GRBL Homing ($H), and your own custom macro "Homing.txt" (H) in macros directory.

Built-in "Go Home" (HZ) button that sends a Z5 command, then X0 Y0, for use after the machine is calibrated to 0,0,0

Ability to Directly Type and Send GCode and GRBL Commands Manually via the Command textbox and Send button on main panel

Monitoring of GCode and GRBL commands being sent, and the results received thereof, properly filtered to prevent monotonous data being displayed

Monitoring of GCode being ran displaying what commands just got sent, and what are about to be sent to the Arduino

Intuitive Tape Deck style Transport for Running GCode

Cycle Start button

Feed Hold button (F1 key), which subtley glows red when the Feed Hold is ON. Click Cycle Start to resume running the GCode job.

Reset button (Escape key)

Large Touch Screen-Friendly buttons for main functions, and for the important real-time functions like the Reset and Feed Hold buttons

Includes Many "Skins" for User Customization of Main CNC Screen (press F3/F4 buttons to run through the skins)

Cameras

Cameras. The ablity to show up to 3 cameras on the screen at one time.

Camera Scenes, with 5 Camera Scene buttons for 5 different camera views, with or without OpenCV.

Open CV (Computer Vision) for auto hole locating.

Open CV Settings Adjustment Screen

"Screen To Machine" Calibration for establishing hole movement distance in Pixel to Machine Travel in mm.

Automatic Locating of Drill Hole or other reference marker using Computer Vision, to help set the machine position to X0 Y0, or to reposition the machine to X0 Y0, after losing position.

Self healing USB cameras for when USB ports change. This makes sure that the software does not try to open the wrong camera device, which helps prevent USB ports from locking up, and it can even help prevent your PC from locking up and going "blue screen", and needing to shutdown, and reboot. It can be especially helpful when you have 2 cameras with the same device name in Windows, where other software of less quality would get confused, and lock up your machine.

Powerful GCode Generation! Many Features of Convenience, Speed of Use, and Ease of Use when Setting up a Job for GCode Generation

Auto Sizing of Drawing in GCode during GCode Generation

Auto Centering of Drawing in GCode during GCode Generation

Auto Selection of Swap X and Y (Portrait or Landscape) of Drawing in GCode during GCode Generation

Click One Button for perfectly Sized and Centered GCode Generation, including Auto-Orientation for Landscape or Portrait. No Thinking Required. Now, literally a 4 year old child can draw something, and click a single button to generate perfect GCode, perfectly orientated and sized for maximum size, and perfectly centered.

New Features of Speed of Job Time and Reliability (in GCode Draw)

Sorting of GCode for the Shortest possible Tool Path, including the ability to even draw lines in reverse (from how the line was originally drawn), if need be, for a shorter overall tool path, resulting in dramatically faster job times. Sorting gets rid of all the unncessary machine travel and wasted time. Since the overall length of carraige travel is dramatically reduced, the chance of job failure is dramatically reduced. And not only is the overall tool path dramatically shorter, but it is also the type of machine travel that gets removed from the job during the sorting of GCode that is so important. It is the faster G00 travel that gets almost all removed when sorting the GCode. Without sorting, this would often be longer G00 lines, moving the head back and forth long distances to say draw a tiny dot. These long fast G00 moves tend to cause more jolting to the machine, and it also throws more back EMF due to the higher travel speeds. That is exactly the type of machine travel that gets virtually removed when sorting the GCode, and this results in a dramatically more reliable running on jobs, plus much less noise as there are fewer of the fast and long G00 runs that tend to make more noise. Sorting the GCode / Tool Path gives you a double benefit in reliabily, plus a massive reduction in job time. Sorting of GCode is the most important feature added to version 1.1 of GCode Draw.

Real Time GCode Planning, including Real-Time, "On-The-Fly" GCode Changes and Optimization (in NewRAD CNC controller)

New Real-Time GCode "Planner" in the NewRAD CNC controller allows for dramatically faster machine movement without crashing, including 3 new checkbox options.

1. Slow Angles

2. Slow Ends

3. Slow Diagonals

"Slow Angles" slows down the Feed Rate proportionally based on the angle of the next line, thus allowing for higher feedrates and accellerations in general.

"Slow Ends" (of straight lines) chops off a small amount from the ends of straight lines, proportionally to the length of line and Feed Rate, usually between 3mm to 18mm, and then slows down the Feed Rate of the chopped off bit proportionally based on the the speed of the feedrate of the longer first part of the straight line that was chopped in two, and on the angle of the next line. Since the speed of the machine is slowed way down before it ever even gets to a corner, this allows for no jolting on the corners, which lets you in turn crank up the feedrate and accellerations to ridiculous and insane speeds without crashing. Speeds so fast it is almost embarrasing. All of that together allows you to draw rectangles and such at speeds so fast, and so smoothly on the corners, that is just amazing to watch. A bit of caution. Speeds that ridiculously fast do increase the volume level of your machine quite a bit, and the noise can be a bit bothersome, but the speed the machine is running at is so fast, it is humourous, if not a bit scary. It is fun and amazing to run at those speeds but it is also a bit unnerving. Just because you can run at super speeds does not mean you have to all the time if you don't want to. You can still run very fast and very smooth at much slower speeds that are still very fast, for a more tranquil CNC experience. Drawings with long straight lines can really benefit from the "Slow Ends" option.

"Slow Diagonals" slows down diagonal moves proportionally the amount that they are diagonal. This is done to protect CoreXY machines with loose belts which have a tendency to jam on fast diagonal moves. The more diagonal, the more they tend to jam. This new feature prevents those problems.

Each of the 3 "Planner" check boxes slow down the machine as needed based on the different situations and metrics of the coming lines of GCode running at the time. These 3 Planner check boxes allow the NewRAD CNC Software Controller to prevent the machine from jolting around on corners and sharp angles, which can cause back EMF and result in lost steps, or stopping of the job. Preventing machine jolting on sharp angles also prevents wear and tear on your CNC machine, and can help save it from tearing itself apart. Since the machine is better protected from these jolts, this allows the user to crank up the Feed Rates, Motor Speeds and Accelerations to levels much much higher than without these 3 things, slowing the machine down dynamically as needed per each line of GCode. This makes for a dramatically faster tool-head movement and a much more dramatic presentation of your CNC machine running at blazing speeds, while still maintaining very little jolting on angles. These features were designed with a CNC draw machine in mind, where tool-head speeds can be very fast.

New On-Screen Visual Alerts for when Control, Alt, and Shift keys are pressed, for user feedback and added awareness when using T1 Transport buttons, so the machine moves the distance expected. Other protections added to protect against keys getting stuck in down position.

New Draw Features added to "Rotate" section of "The Repeater" in GCode Draw

Spiraling Draw Objects

1. Spiral Rotation. This makes the object that is be copy/rotated in a circle move in or out of the circle as it rotates. It increases or decreases the radius to the center of rotation, thus giving a spiral effect.

...but to be a good spiral, you really need to shrink or grow the object as it rotates. ...so that is the next feature.

2. Decrease Object Size as it spiral rotates. (You can also type in a negative number resulting in an increase in object size as well).

...but to be a really good spiral, the object needs to shrink in proportion to the radius as it is spiraling outward. ...so that is the next feature.

3. Decrease Object Size as it spiral rotates, in proportion to radus from center of spiral.

Also, shrinking objects can shrink past a size of 0, and go into a negative size resulting in larger and larger objects. This can yield some cool graphic effects, especially when moving the drawing around with the Shift and Alt keys, while moving the mouse. For example, a spiral of circles can turn into something that looks like a worm twisting and turning about on the screen. This is just one of many examples of how this effect makes a drawing come alive and transform into something that you never thought it could be. And it all started with just a single simple object, repeated and spiraled, while shrinking proportionally to the radius from center. All this drawing power in the user's hands for just a few clicks. And then hold down Shift and Alt, and have fun transforming your drawing into new things.

Before there was just the ability to rotate copies of a drawing object or collection of objects in a circle, with parameters of degrees and number of times to copy the object around the circle. Now in GCode Draw 1.1 you can make the object spiral in and out of the circle as it rotates, growing or shrinking in size, and with the option to grow or shrink proportionally with the distance from center. This makes for some great graphic effects. After you have made a spiral of shrinking objects, hold down the Shift and/or Alt keys while moving the mouse to manipulate the rotation parameters of the objects and make the drawing come alive on the screen. ...contorting, transforming, etc. This is the most creating and fun to use part of the entire software. You can start with almost nothing, like an elipse (circle/oval), rectangle, triangle, line, bezier curve, or collection of such of any of the above, copy rotate it, with options of spiraling and shrinking or growing in size as it rotates. Select all the objects on the screen, hit the Shift or Alt key while moving the mouse, and you can create a masterpiece in minutes, if not seconds, and have a lot of fun doing so. Then turn it to GCode with one click.

New Job Time Reporting, Estimated Job End Time, Visual displays for where you are in a job, including line index per line count and a new Job Progress bar. New On Screen Time Clock

Most importantly, all the bugs that were present in version 1.0 have now been fixed in version 1.1 of both NewRAD CNC and GCode Draw. Now the controller works much better, as does GCode draw. Both are much more stable. The powerful 2 in 1 software combo now provides a much more enjoyable, reliable, powerful, and fun CNC experience. The new features give the user more power to do new and creative things with their CNC, more easily, and with less hassle, and in much less time, especially in reduced job times with version 1.1, due mostly to the new GCode tool path sorting feature.NewRAD CNC works with all GRBL-based CNC machines.

Other Features:

Text-To-List function

Includes a Text-To-List function allowing for quick copying and pasting of GCode from other software into NewRAD CNC, without having to save the GCode to a file first. This can be handy for testing, or when your have GCode from another app or website copied to the clipboard that you pasted into the GCode textbox in the applicaiton in order to run it, but when there is just no need to save the GCode to a file. The GCode listbox, and not the GCode textbox, controls the index of what line of GCode is running. The cursor is held in the middle of the listbox so that you can see what just got sent to the arduino, as well as what is about to be sent.

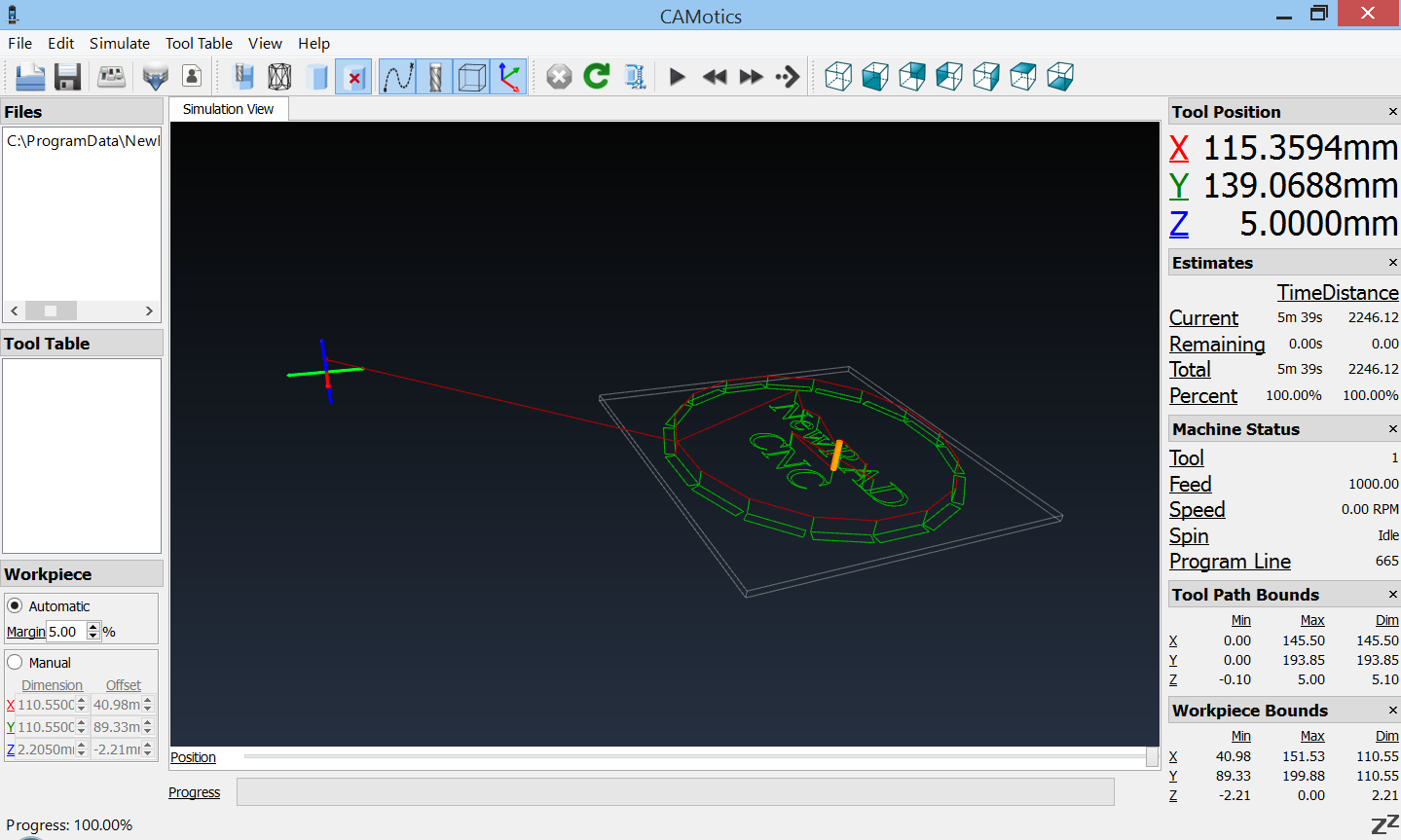

3D Viewer

3D Viewer Button to View and "Play" GCode Toolpath in 3D using free external software by CAMotics, installed separately.

Custom Screens

NewRAD CNC software becomes part of your CNC machine and therefore, it needs to look and feel like a machine. And at great cost, we made it do just that. NewRAD CNC includes the following customized Color Schemes or "skins", in addition to the default skin above, plus more colorful skins included in the installation. You can change the skin with the F4 (next) and F3 (previous) keys. When you find the skin you like best, then click the Save CNC Settings button, and the next time you start the program, it will start up with that color scheme ("skin"), thus allowing you to "pimp your ride".

NewRAD CNC is a great value plus it has solid reliable performance, quick responsive screens, fast metering, and an optional GCode Draw program completing the entire CNC experience, from design to end product, all in one software suite.

GCode Draw OverviewTo See ScreenShots and Feeatures of GCode Draw, click here: ScreenShots and Feeatures of GCode Draw

GCode Draw is a powerful 2D draw program designed specifically for CNC usage. It lets you make 2D drawings and designs quickly and easily. Generate GCode from your drawing with one click, and then load that GCode into the integrated NewRAD CNC Controller with another click. This allows for rapid fire CNC fun.

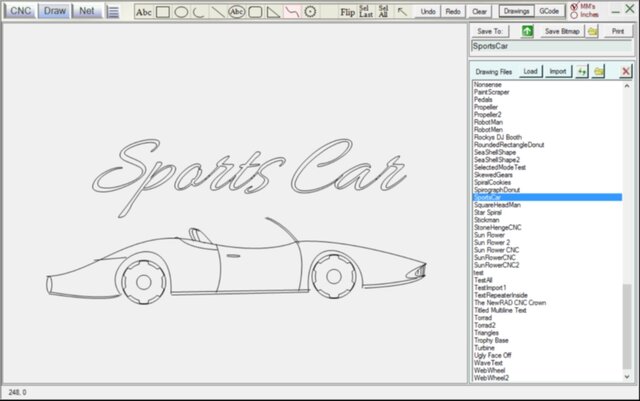

Having both softwares in one large integrated software package has many benefits, like speed, ease of use, file organization. There is no being forced to fumble with the small cumbersome Windows dialog box for file selection. Your drawing files are preloaded into a list box on the right side of the screen, ready to load into the draw program with a double click. Then another click to load the generated GCode into the controller. The seamless integration lets you fly through all of your basic CNC operations. The result is less hassle, greater production, and way more fun.

GCode Draw is targeted at the hobbyist who needs something quick and easy for creating 2D drawings and who wants to avoid the time-consuming complexities of heavy 3D software.

The GCode generated from the 2D drawings can be made to be multi-pass when milling, ...kind of a "thick 2-D". The 2D drawings can be stacked to achieve a 3D drawing in GCode to be ran as a single job, or multiple jobs. The NewRAD CNC controller can run full 3D, 4-axis GCode files generated from other software. It is just the GCode Draw portion of this software suite that is targeted specifically at 2D users for quick and easy 2D drawing and 2 1/2D GCode generation.

A fairly large percentage of CNC jobs are actually 2D jobs, like drawing or cutting 2D profiles out of a material, like with a laser or plasma cutter, Often these types of jobs are impromptu type jobs where you just want to do something quickly for fun. That is where GCode Draw can be a perfect solution.

Since this product is 2D, it is great for things like making signs, or things with text on it, and doing so effortlessly quick, without getting bogged down in the heaviness of using a complicated 3D CAD program with many steps.

When creating your drawing, type the name of your drawing only one time, and that name will be used automatically for all file operations such as saving the drawing file, saving the bitmap thereof, or when saving generated GCode to a file. And each file will automatically be saved into the proper directory for that file type automatically. You never have to fool with the Windows File Dialog Box to search for the directory of where your files are.

There are also various folder buttons in the app that when clicked on will open up Windows Explorer to that given directory with your files right there. You never have to search for your files using the Windows File Dialog box. Not having to deal with that makes using the app so much better than if you had to deal with it, like you do with other CNC software and other Draw software as well. It keeps operations in the app fast short and sweet, resulting in rapid fire CNC fun. That's what it is all about in this software. Add in the integration of the Draw program, the GCode Generation, and the CNC Controller for GRBL all in one integrated seamless design, and this application suite suddenly becomes a fantastic way to interface with the entire Drawing To GCode to CNC Controller cosmos.

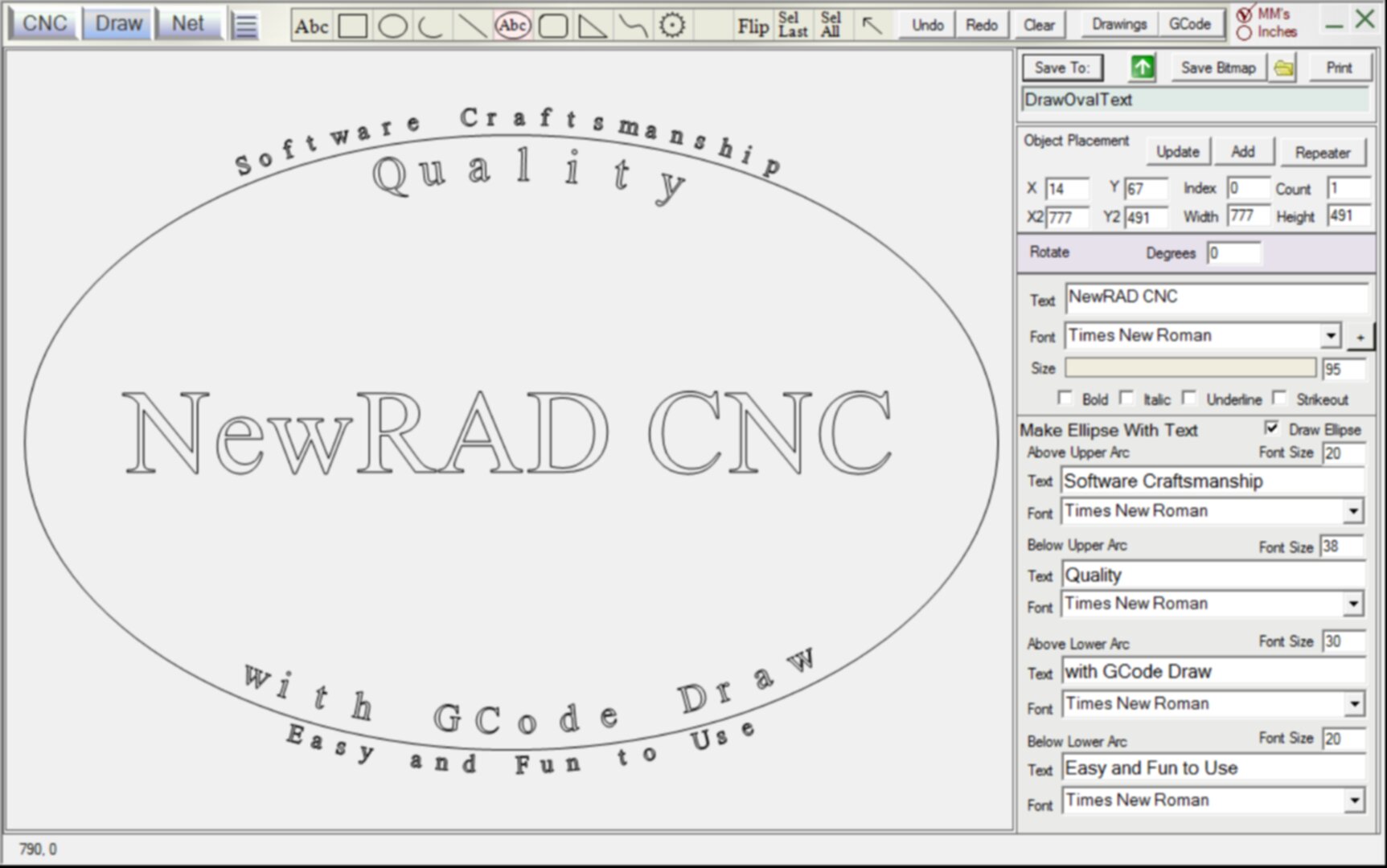

The main features of the GCode Draw software are:

You can draw:

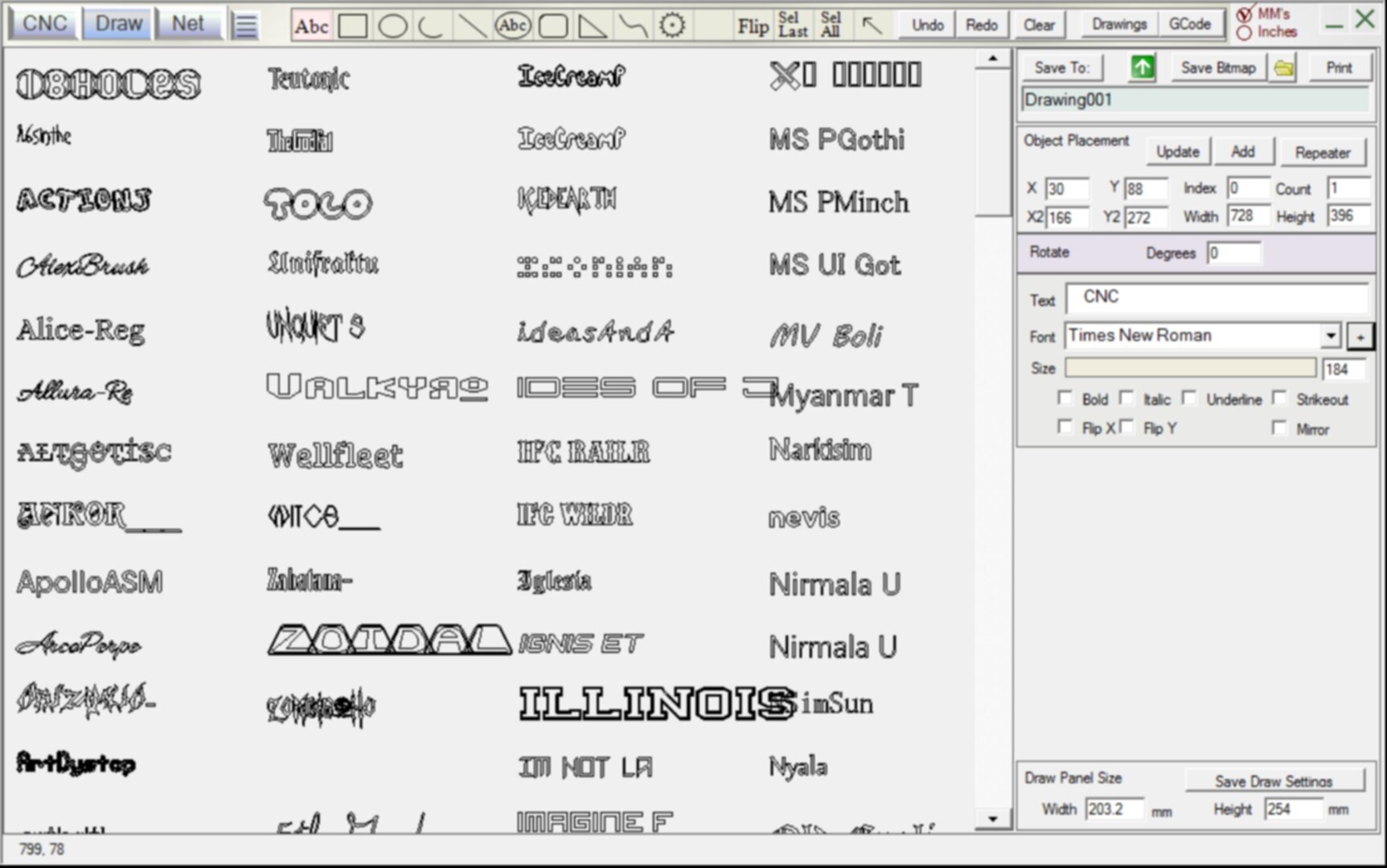

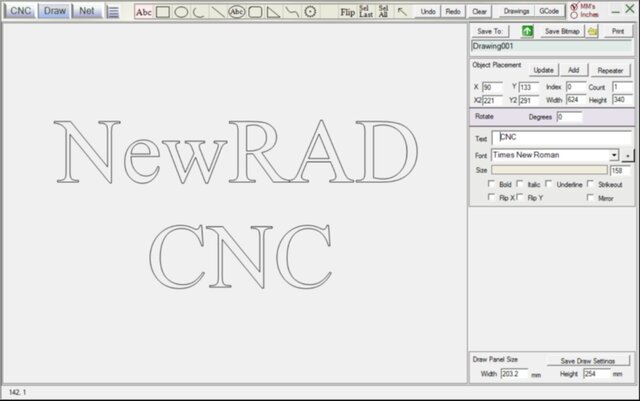

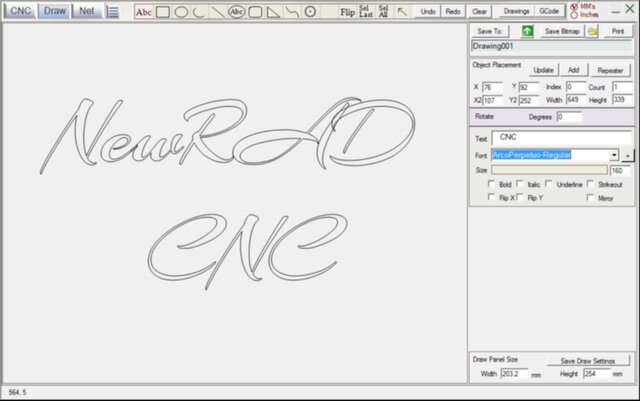

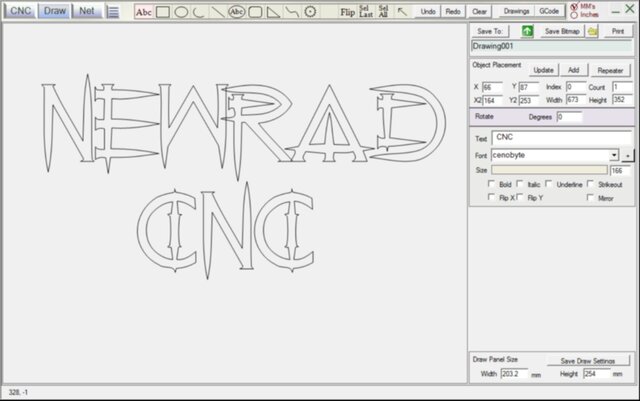

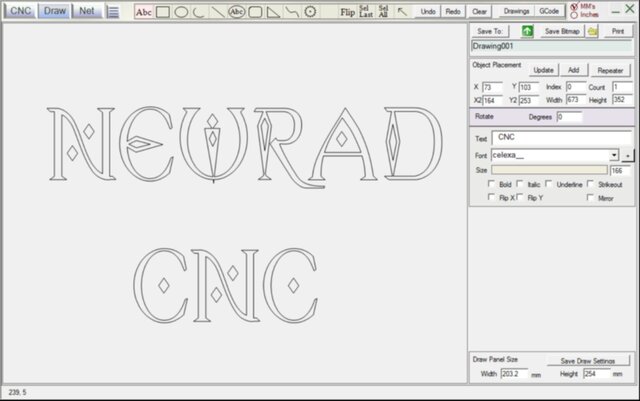

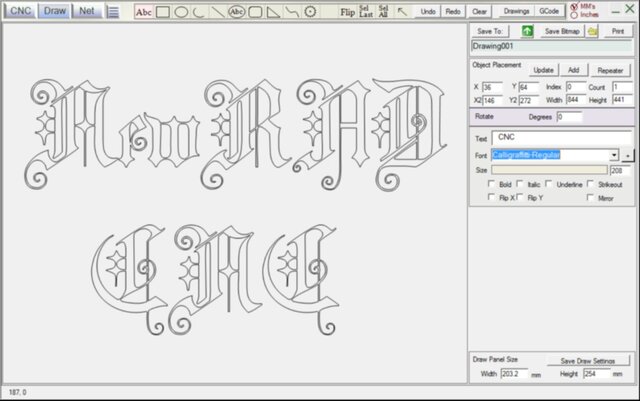

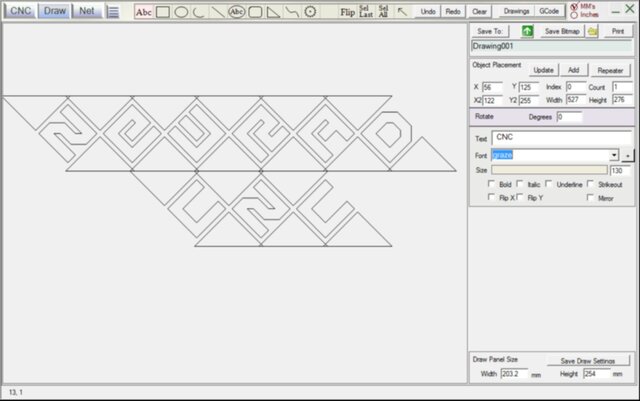

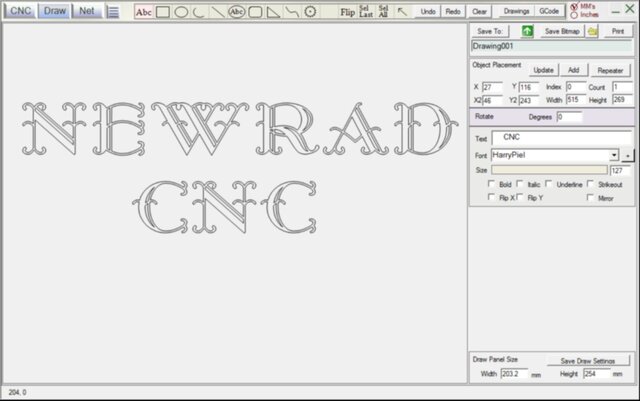

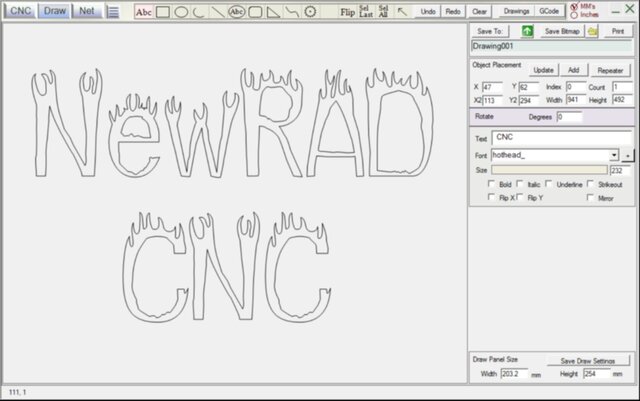

Text

Circles

Ovals

Squares

Rectangles

Gears

Rounded Rectangles

Arcs

Triangles,

Lines,

Bezier Curves,

Curved Text

Oval with Text and Curved Text above and below (a classic).

All with just drawing it with the mouse.

Try holding the control, shift and alt keys on various draw functions for different effects like automatic centering, squaring of squares and circles, copying a selected graphic object, etc.

It is a powerful drawing program, and from there, you can easily take it to GCode, and load that into the NewRAD CNC controller. All integrated and self-contained. And it is all designed for a typical CNC hobby user that wants to be creative quickly, drawing something and printing it out right there with a few clicks.

But wait there's more to the draw program.You can also...

Repeat objects in rows and colums, and inner and outer (like a square inside a square inside another square, and so on. And lastly you can repeat an object or selection of objects while rotating those objects. With these 3 types of repeating mechanisms, you can do a whole lot of things.

It also has an object flipper, which lets you flip a selection of objects left/right/up/down with the arrow keys. This is highly useful.

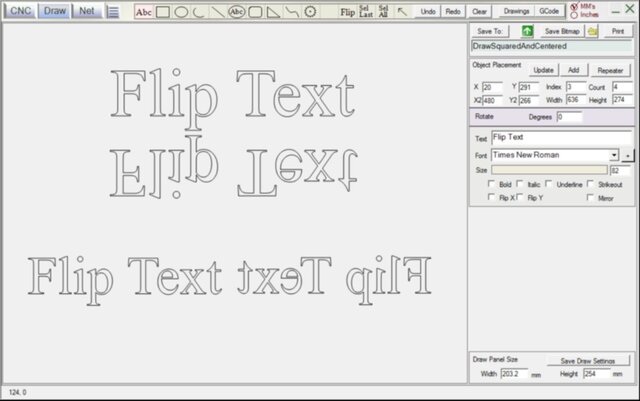

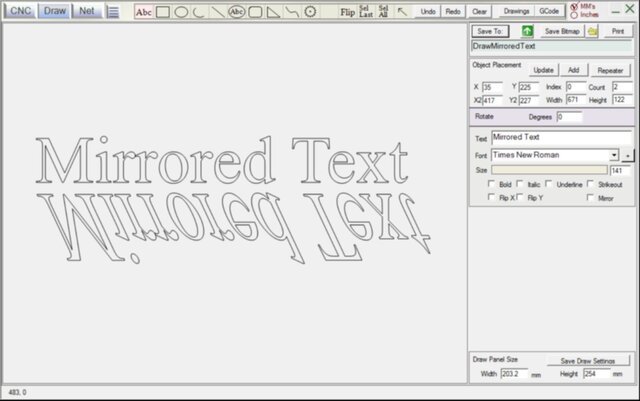

You can also Flip Text, upside down, and left to right, and mirror text.

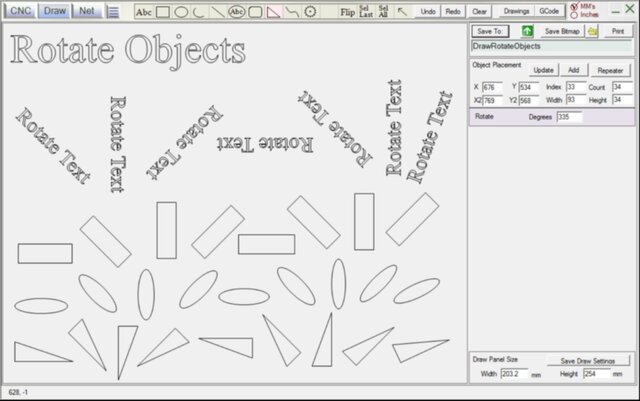

You can rotate text or a single drawn object, like an oval, rectangle, square, or triangle, etc.

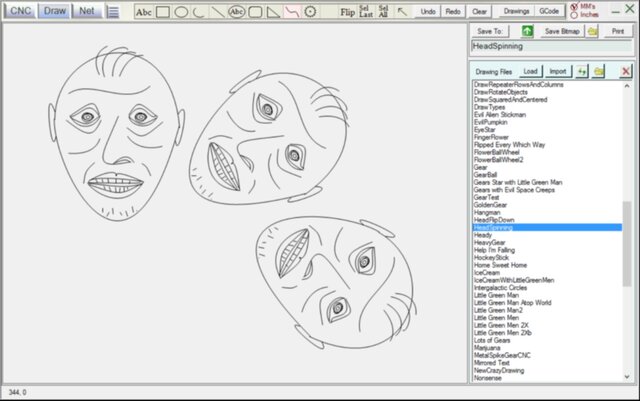

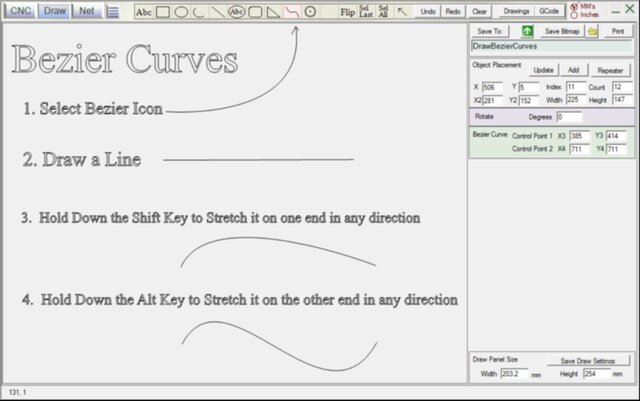

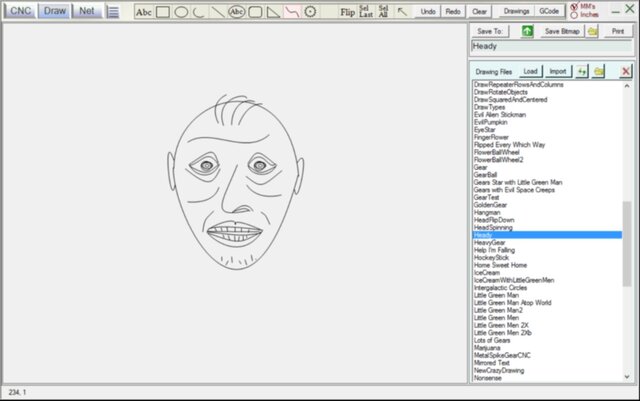

The most important tool for drawing things like faces or things with curves is the Bezier Curves tool. Draw the beginning and ending points and then use the shift and alt keys to stretch the curve of the line between the two end points. This makes drawing curves very easy. A non-artist can quickly draw some faces or other objects that curved lines with the bezier curve tool.

You can upload your drawings so that others can use them too.

You can browse drawings of others whom have uploaded their drawings, and download them to your Drawings directory with one click

The program comes with 163 built-in fonts specifically tailored for CNC usage.

To See ScreenShots and Feeatures of GCode Draw, click here: ScreenShots and Feeatures of GCode Draw

Contact Us

www.newrad.com